|

|

|

|

|

|

ENVIRONMENT |

|

| |

| Natural resources, especially the subsoil ones, play a vital role in a nation's progress and prosperity. But mining of these resources is a complex and intensive process that may cause environmental and social challenges. Hence, maintaining a fine balance between economic growth and sustainability is vital. |

| At Vedanta Resources, we adopt global leading practices to reduce and minimise the environmental impacts of our operations. Reduction of water and energy consumption, minimising land disturbance and waste production, containing pollution, and conducting successful mine closure are some of the measures we have undertaken to minimise our impacts. |

|

|

| US$ 39 MN |

| Environmental investment |

|

|

|

|

| |

|

| |

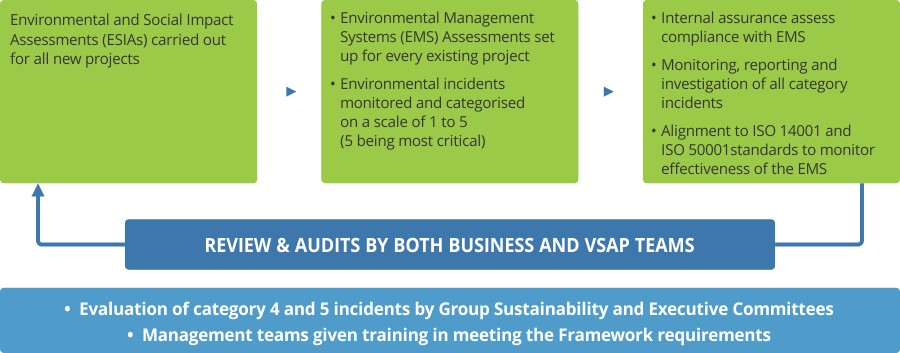

| APPROACH |

| We work with our partners and the neighbouring communities at project sites to bring far-reaching socio-economic and environmental benefits to the region. We adopt a systematic and process-oriented approach, underpinned by a spirit of entrepreneurship. This approach has not only resulted in mitigating impacts but has also created value for our stakeholders and helped us secure the social licence to operate. |

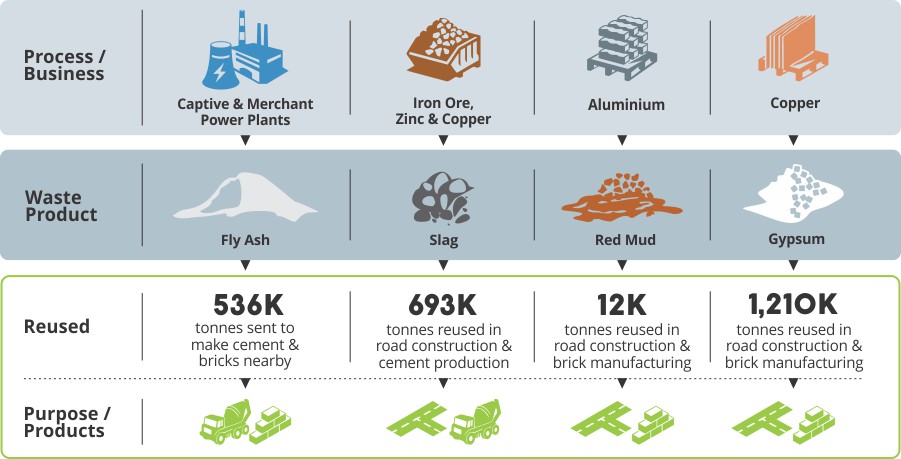

| Our Sustainable Development Framework includes a toolkit of policies, standards and guidance notes to rigorously manage environmental impacts. For the environmental priorities arising from the materiality process, we have developed specific objectives and targets, and review performance against these issues on a periodic basis. We are working towards implementing our Biodiversity Action Plans and are also finding new and innovative ways to reduce and recycle waste from our operations including fly ash, red mud, phosphorous gypsum, copper slag, etc. |

|

| |

| PERFORMANCE |

| During the reporting period, there were no serious environmental (category 4&5) incidents, as defined by Vedanta Incident Categorisation Matrix. 48 of our 52 operations are ISO 14001 certified and the remaining shall be certified in the near future. |

|

|

Fly ash recycling increased

to 47% in FY 2015-16 from

31% in FY 2014-15 |

|

|

| All subsidiary businesses have been assessed against the identified material aspects related to environment i.e. water, energy, biodiversity, waste management etc. through internal VSAP audits, and action plans are in place to close all identified gaps. |

| |

| LOOKING AHEAD |

- Achieve ISO 14001 certification for the remaining sites

- Align our energy and carbon strategy with INDC's objectives in lieu of COP 21 commitments

- Capacity building on biodiversity management including ecosystem services

- Continue to explore opportunities and areas to increase the fly ash utilisation

- Engagement with independent expert to review the high priority/risk tailing facilities

|

| |

WATER

| Water is a critical component in mining and securing an adequate water supply has emerged as a key challenge for the sector globally. |

|

|

|

| We are committed to minimise our water footprint and reduce the freshwater consumption by reusing as much water as possible in our processes. |

|

| Preliminary Tailing Risk

Assessment (Internal)

completed across the Group |

|

|

| Approach |

| Our approach is outlined in our water policy and delivered through our water management standard. We facilitate the integration of water management into decision-making processes for all our new and existing projects. This ensures that all necessary measures are in place to avoid, minimise, or, in some cases, compensate for the impacts of our projects. All our subsidiary businesses have conducted a water-screening assessment to identify sensitive water resources, aquatic habitats and any known or suspected water resource constraints in proximity to each operation. |

| Our operations exist in areas of varying degrees of water stress. Accordingly, our water management plans have been chalked out carefully keeping in mind the water status of each location. For water-stressed areas such as Rajasthan in India, we implement water conservation projects and follow a zero discharge philosophy. For operations which are not in water-stressed areas (such as KCM, CMT and Lisheen), we ensure programmes are in place to protect this precious resource. |

| But across all our operations, we follow the water conservation hierarchy of reduce, reuse and recycle. We also focus on rainwater usage and groundwater recharging through rainwater harvesting. Significant strides were made in all four areas during the reporting period. |

|

|

|

|

| |

| Reduce |

- Replaced/repaired defects like leakages, overflows (process losses) etc. in the reticulation system at KCM,

HZL Jharsuguda, and BALCO, while Zinc International undertook an internal water audit. Total estimated water

savings through these interventions is around 240,000 m3

- KCM played a major role in water savings through water recovery at the conventional thickeners at KIBU and

recirculation of water from TLP back concentrator at Nchanga

|

| Reuse/Recycle |

- Commissioned an ETP at the BALCO smelter which resulted in savings of 35,000 m3

- BALCO also installed a 4,800 m3/day RO system. The treated water is used for cooling purposes and gardening. The

initiative led to 100% utilisation of liquid effluent and 23% reduction in the specific water consumption

- Treated CPP blow down water is used for industrial and domestic use; minimising the requirements of the fresh raw

water at HZL, Jharsuguda, and Cairn India. This results in approximate savings of 80,000 m3

- Our Cairn India and HZL units in Rajasthan, India are meeting 66% and 36% of their total water requirement

through recycled water

- Cairn India adopted Reedbed technology for domestic wastewater treatment and utilised the treated water in

greenbelt development

- KCM is undertaking a water recycling project to improve the quality of water, downstream of Muntimpa. It has

already invested $0.5 mn in the interim to provide a backup water abstraction point on Chati stream which

supplies water to Kalulushi residents

|

| Harvest |

- Operations of HZL and Sesa Iron Ore subsidiaries have taken up specific measures to improve rainwater harvesting. This year 1.75 mn m3 rainwater was harvested

- TSPL constructed rainwater recharge ponds of 115,000 m3

|

|

|

|

| Performance |

| Most of our operational processes have been designed to be 'zero discharge'. Wastewater is treated and recycled for cooling and other applications at our units. Additionally, effluent and sewage treatment plants are installed at many locations to recycle water. |

| Due to the high water table in Zambia, Ireland and Australia, we have to 'dewater' (remove) a large quantity of water from the underground mines. This water is discharged into nearby water bodies, complying with applicable regulatory limits, and treated in effluent treatment plants. Further, Cairn India utilises the abundant supply of sub-surface saline water to meet its operational and domestic water needs, to avoid any risk to the freshwater resources of the region. |

| In the reporting year, all our businesses contributed in conserving this precious resource and helped us surpass our water conservation target. We saved 7.2 mn m3 against the targeted savings of 2.3 mn m3 |

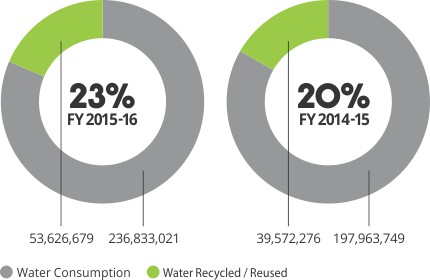

| The Group's water conservation efforts, across its subsidiaries on a global basis, led to the recycling of nearly 53.6 mn m3 compared to 39.5 mn m3 last year, which fulfilled 23% of our overall water requirement. We withdrew 359 mn m3 of water compared to 362 mn m3 in the last reporting year, with 56% from groundwater, 43% from surface water and 1% from rainwater and utility. |

| |

| Specific Water Consumption |

| Businesswise Break Up |

(m3 / unit of production output) |

|

| UNIT NAME |

| SPECIFIC WATER CONSUMPTION |

|

|

|

| HZL - Mines |

0.53 |

0.46 |

| HZL - Smelters |

7.35 |

6.35 |

| Skorpion Zinc |

22.96 |

25.96 |

| Lisheen Mine |

0.02 |

0.04 |

| BMM |

0.87 |

1.02 |

| KCM |

263.36 |

179.76 |

| Sterlite Copper |

7.26 |

7.09 |

| BALCO |

1.87 |

2.32 |

| Lanjigarh |

2.66 |

2.49 |

| Jharsuguda |

0.48 |

0.46 |

| SSL Iron - PID |

0 |

2.50 |

| MEL |

3.65 |

3.93 |

| TSPL |

0 |

2.35 |

| Cairn India |

1.03 |

1.13 |

|

|

|

| In the reporting year, all our businesses contributed in conserving this precious resource and helped us surpass our water conservation target. We saved 7.2 mn m3 against the targeted savings of 2.3 mn m3. |

|

| |

| Consumption & Conservation Snapshot mn m3 |

|

water recycling in FY 2015-16

as compared to 20% in the previous year |

|

|

|

|

| While our actual water consumption increased, the specific consumption (i.e. consumption per unit of production) reduced at all major businesses, as a result of process and technological interventions. Some businesses, however, noted increase in specific water consumption primarily due to reduced production. |

| |

| Responding to the Environmental Challenges |

|

| Lisheen mine received summons from the Environmental Protection Agency (EPA) in October 2015 for a breach

of our Integrated Pollution Control Licence (IPCL). The breach relates to non-compliant water emissions during a period of time that the mine was recovering from the underground flood, which occurred in February 2015. A report on the incident, which was submitted to the Authorities, concluded that although emission limit values for a number of chemical parameters were exceeded, there was no or minimal impact on environment. |

|

| Two proceedings have been initiated in the UK by two English law firms who allege that people of Zambia have suffered loss and damage and amongst other things, personal injury as a result of KCM's operation in Zambia. The claimants have sought a mandatory injunction to remediate the damage caused by the discharge of harmful effluent in the river body. The allegations made against Vedanta Resources Plc and KCM goes back to 11 years. While these allegations are being investigated and the matter is sub judice, we have demonstrated our commitment to environmental stewardship and over a period of ten years, we invested more than US$ 3 bn in the region towards environmental initiatives including state-of-the-art clean technologies, upgrades and expansions. |

| Below is a glimpse of some of the key environmental programmes undertaken over the years: |

- US$ 440 mn invested to commission an eco-friendly Nchanga smelter resulting in a massive improvement

in capturing sulphur, from 35-50% to 99.98%

- US$ 30 mn spent to refurbish infrastructure at tailings leach plant, resulting in a consistent improvement

in zero discharge at pollution control dam

- Consistent compliance of underground water quality below the legal limit following a US$ 17 mn refurbishment of water infrastructure

- A comprehensive water recycling project under implementation to improve the quality of water downstream of Muntimpa (TD5)

- Investment of US$ 230 mn in the new concentrators at Nchanga and Konkola resulting in a smaller

environmental footprint and zero discharge system

- Plantation of over 72,000 trees between 2007 and 2015 within KCM operations and restocking over 180,000

fingerlings in the community since 2009

|

|

|

| |

| |

|

|

| MAKING EVERY DROP COUNT |

| Various water-friendly interventions at KCM & TSPL |

| Konkola Copper Mines and the Talwandi Sabo Power Limited (TSPL) are both water-intensive facilities , and thus provide an opportunity for huge savings. In the reporting year, various water friendly interventions were introduced at both facilities. |

|

|

| |

|

| |

| KCM |

| KCM identified three major interventions: |

| 1 Optimised water recovery by installing pumps

to recycle process water back into the process |

| 2 Replaced worn-out pipes and other fittings in

the reticulation system |

| 3 Raised awareness among employees on

water conservation |

| Due to the above measures, the water consumption at KCM went down by over 45%. With these measures and other projects, KCM in total has saved 2.65 mn m3 of water this year. |

|

|

| TSPL |

| TSPL formed a cross functional team to drive water conservation activities. The team identified root causes and came up with focussed solutions such as attending the leakages, improving inspections, and conducting audits, all aimed at reducing raw water consumption. |

| Interventions by the water conservation team led to decline in raw water consumption by over 38% at TSPL. Specific raw water consumption went down to 2.7 litre/kWh in FY 2015-16 compared to 4.4 litre/kWh in the previous year. |

| The target is to further bring down the consumption of water to 1.8 litre/kWh by taking up WHS and HSS interconnection, commissioning of recycling pump house and exercising tight control over COC control chart. |

|

|

|

| |

|

|

| |

ENERGY & CARBON

Climate change is a rapidly growing concern and poses a fundamental threat

to the entire world. Tackling this concern calls for exploration and adoption

of innovative technologies

that maintain ecological balance without

compromising on economic growth. |

| For a natural resources Company like Vedanta, energy constitutes a major part of input costs, which if managed efficiently can sustain profit margins. We are aware of the business case that energy management presents, and hence we enhance energy efficiency at our operations by leveraging a combination of new technologies. |

| To add further robustness to our energy programmes, our subsidiary businesses are upgrading their business management systems to receive the ISO 50001 energy management accreditation. |

| Approach |

| We understand that changes in regulations, operating / physical parameters, carbon taxes and consumer behaviour arising due to climatic change risks may have the potential to generate a substantive change in our business operations, revenue or expenditure. As an example, the change in UK GHG reporting regulation, commitment towards Paris summit and India's as well as Zambia's increasingly proactive and aggressive stance towards managing their GHG inventory may drive stringent regulations leading to higher fuel costs. |

| This may ultimately reduce operating margins and profits for our businesses. All these changes pose a potential compliance risk for our operations, which may result in direct financial implications like financial sanctions or indirect financial implications such as loss of reputation, which can affect stakeholder confidence. After the recently concluded Paris agreement on Climate Change (COP 21), we are working to formulate a strategy on Climate Change that is aligned with the Intended National Determined Contribution (INDC) for the countries in which we are operating. Our Sustainable Development Framework includes an Energy and Carbon Policy, and an Energy and Carbon Management Standard whereas our long-term strategy for addressing energy and climate change issues focusses on improving energy and process efficiency and diversification of our energy portfolio at all operations, where it is physically and economically feasible to do so. |

| Performance |

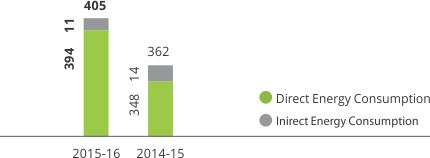

| As Vedanta is part of an energy intensive industry, our direct and indirect energy consumption is in the order of 405 mn GJ, higher than last year mainly on account of higher production and commissioning of units (smelter and power plants). But our energy consumption per unit of production has maintained a balanced trend, except for a couple of businesses like Skorpion Zinc, HZL smelter and MEL owing to low production as compared to the previous year. |

|

| |

| Specific Energy Consumption |

| Businesswise Break Up |

(GJ per tonne of Product) |

|

| UNIT NAME |

FY 2014-15 |

FY 2015-16 |

| HZL - Mines |

0.49 |

0.42 |

| HZL - Smelters |

17.04 |

17.10 |

| Skorpion Zinc |

20.03 |

26.31 |

| BMM |

0.42 |

0.44 |

| Lisheen Mine |

0.38 |

0.38 |

| KCM |

51.96 |

35.29 |

| Sterlite Copper |

8.42 |

7.72 |

| BALCO |

58.54 |

54.94 |

| Lanjigarh |

8.65 |

7.95 |

| Jharsuguda |

53.59 |

52.53 |

| SSL Iron - PID |

0.97 |

0.92 |

| MALCO |

9.47 |

12.43 |

| CAIRN |

1.47 |

1.87 |

| TSPL |

0 |

5.92 |

|

| |

| Absolute Energy Consumption |

tons of CO2 equivalents |

|

|

|

|

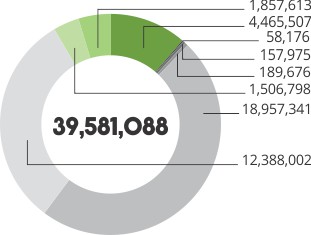

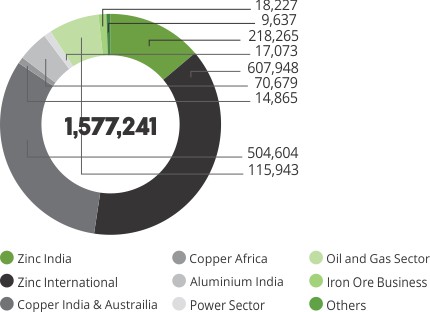

| Greenhouse Gas Emissions |

tons of CO2 equivalents |

|

| (By Business) |

| Scope 1 - FY 2015-16 |

|

| Scope 2 - FY 2015-16 |

|

| |

| BALCO smelter, Vedanta Ltd. - Jharsuguda Independent Power Plant and HZL - Zawar mines bagged National Energy Conservation awards in various categories. |

|

|

| |

| We calculate and report Greenhouse Gas inventory i.e. Scope 1 (process emissions and other direct emissions) and Scope 2 (purchased electricity) as defined under the World Business Council for Sustainable Development (WBCSD) and World Resource Institute (WRI) GHG protocols. Our GHG intensity has increased primarily due to slowdown in production. The increase in our absolute GHG emissions is due to addition and ramping up of our power plants at TSPL, Aluminium and Power operations. |

| Energy Efficiency Measures |

| In FY 2015-16, we conducted an internal benchmarking exercise with a view to understand the energy consumption practices of our subsidiaries as well as to create a sense of competition within Vedanta to accelerate conservation. Some of the key projects are detailed below: |

- HZL incorporated changes in Variable Frequency Drives in its mines and smelters, and further invested in

various operational improvement projects leading to energy savings of 26,375 GJ

- BALCO implemented various process improvement projects like increase in current efficiency and reduction in average pot voltage in pot line, installation of VFD in atomising blower to regulate current and regulation of mill load which resulted a total saving of 6,422 GJ

- Black Mountain mine and Skorpion Zinc have implemented

various efficiency measures like retrotting of equipment,

installation of daylight switches and LED lights which have

accrued energy savings of 94,745 GJ

- Cairn India has installed solar water heaters, solar lights, and LEDs, leading to 233,941 GJ of energy savings

- KCM brought in a host of changes in its operational devices like air compressors, saving 84,434 GJ energy

- Vedanta - Jharsuguda executed reduction in auxiliary energy consumption by optimising ID fan power,

compressed air use, pump house energy reduction, and cast house furnace. Further process improvement

projects like reduction in current efficiency by reduction in process variance and implementation of

advanced technology for smelting have yielded total energy savings of 34,046 GJ

|

| Clean Energy |

|

| Over and above optimising our efficiencies, we also continuously evaluate our renewable energy portfolio. While we currently source less than 2% from renewable sources, we are taking the lead from subsidiaries like Copper Mines of Tasmania and KCM Zambia, where 70% of energy is derived from hydropower. |

| The Group Companies are specifically focussing on exploring innovative and technology-oriented solutions which will lead to conservation of 1.5 mn GJ energy, next year. |

| We remain on a vigil to find opportunities to generate electricity from waste heat. Businesses like Sesa Iron Ore, Sterlite Copper and HZL have installed Waste Heat Recovery boilers with a total capacity of 139 MW. |

| Our HZL subsidiaries have wind farms with installed capacity of 273.5 MW across five states in India. All wind power generation has been registered under the Clean Development Mechanism (CDM) and 511.4 mn units have been sold to the electricity grid in each state, an increase of 52.3% compared to 2012. HZL has also installed a 200 kW rooftop solar system at Udaipur and Chanderiya smelters. |

| Cairn India has brought into fold a myriad of solar solutions. It commissioned solar power generation at all E-houses, producing 455,000 kWh solar energy; introduced solar concentrator technology for wastewater evaporation, generating 251,208 kWh; and installed solar lights reducing diesel consumption by 30,000 litre/month to state a few. |

| Under the UN Framework Convention on Climate Change (UNFCCC), we have registered CDM projects with potential CER of 1.3 mn units, out of which we have accrued 0.42 mn units in FY 2015-16. |

| |

| |

|

|

CONSERVING ENERGY.

ENHANCING COMPETITIVENESS. |

| With a view to harness large-scale energy savings, a root cause analysis was undertaken at Vedanta Ltd., Jharsuguda. Based on the results, a slew of conservation projects were identified and implemented. |

|

|

| |

| ENERGY SAVING |

- Reduction in stub to carbon voltage, pot voltage, compressed air consumption, dead pot voltage, crossover voltage and specific energy consumption of wire rod mill

- Improvement of current efficiency of pots

- Implementation of slotted anode in pots

- Optimisation of compressor

- Online addition of pots in circuit by

fuse blown technology

- HTM heater set point optimisation in GAP

|

|

|

| FUEL SAVING |

- Reduction of HFO consumption in Anode

Baking Furnace

- Optimised usage of compressor in metal

transport vehicle

- Reduction of diesel consumption in production

vehicles by improving engine efficiency

- Optimisation of LPG burner use for ingot casting

|

| OUTCOMES |

| Energy Savings 290,842 MWh/annum |

| Fuel Savings 3,127 MT/annum |

|

|

| |

|

|

| |

BIODIVERSITY

| The impacts of diversity loss on ecological processes might be sufficiently large to rival the impacts of many other global drivers of environmental change. Thus it is no surprise that the United Nations designated 2011-2020 as the United Nations Decade on Biodiversity. |

| At Vedanta, we are conscious that the nature of our operations has implications on biodiversity. Protecting biodiversity is a material concern for us, and we continue to advance on our biodiversity management practices across the project life cycle of our operations. |

| As part of our Sustainable Development Framework, we are committed to protect biodiversity. In order to promote a best practice management approach, we have reviewed all operations through an initial biodiversity risk mapping tool - Integrated Biodiversity Assessment Tool (IBAT) to identify which of our sites are operating within close proximity of protected IUCN areas, important bird areas and key biodiversity hot spots. Further these results are verified by the site assessment by third parties at all operations. |

| All our sites have either initiated or already have Biodiversity Management Plans (BMP) in place. The results of the biodiversity risk screening programme have helped us prioritise our actions. |

| Approach |

| Progress has been made across all businesses to engage experts and establish biodiversity management plans to meet our deadlines. |

| Our dedicated Biodiversity Policy and Management Standard is in line with international standards and guidelines like IFC and ICMM. The BMP is developed to avoid, minimise or compensate the loss of the biodiversity attributes which arise due to a new project or a major expansion. We endeavour to achieve a minimum of No Net Loss (NNL) of biodiversity for projects located in the modified or natural habitat area and strive to achieve Net Positive Gain (NPG) of biodiversity for the project location in the critical habitat. |

| None of our operations are located in world heritage properties. Our Black Mountain mine operations spread across approx. 38,000 ha in South Africa and Skorpion Zinc mine covering approx. 8,000 ha in Namibia are located in key biodiversity areas as identified by Conservation International (CI). Both these operations are governed by robust Biodiversity Management Plans which have been developed by regional biodiversity experts. These sites have identified 3 endangered and 8 vulnerable IUCN red list species and national conservation list species. |

|

|

|

|

|

| The Biodiversity Management Plan of our Black Mountain mine has been reviewed by IUCN. |

| Our policy, technical standard and approach to biodiversity management incorporates relevant aspects of IUCN's advocated approach, and our Black Mountain mine site is currently working in partnership with it to implement a Biodiversity Management Plan that also includes Gamsberg operation. Other businesses too have sought consultation from domain experts in management of various biodiversity aspects. We look forward to cement our relationship with IUCN and support its policies and good practices via our membership with ICMM. |

| Vedanta Ltd. is a signatory to the India Business and Biodiversity Initiative, a national platform for business and its stakeholders around mainstreaming sustainable management of biological diversity into business strategy. |

| Revitalising Ecologies |

| At Vedanta, we are taking various initiatives to rejuvenate the flora and fauna of the locations where we operate. |

| Biodiversity Restoration Programme at KCM |

|

|

| At KCM, to mitigate the impacts of our operations, we embarked on a biodiversity restoration programme. The initiatives taken under this programme in FY 2015-16 include: |

- Establishing a nursery of 1,000 seedlings

- Initiating a community-based tree plantation programme in Kanenga and planting 280 trees so far

- Embarking on progressive rehabilitation of tailings

dams and overburdened/waste rock dumps, where a

total of 10,795 indigenous trees have been planted

|

| Guinness Book Plantation Record at Mansa |

|

| Talwandi Sabo Power Limited (TSPL) set a world record by planting 208,751 saplings in 1 hour on October 30, 2015 in Mansa, Punjab. Over 5,800 supporters from schools, surrounding villages and locals volunteered to make this feat possible on a 200-acre land area. |

|

| Considering the small forest cover in Punjab, these additional trees will help improve biodiversity in the region and specifically in Mansa. |

| TSPL is deeply committed to enhance biodiversity conservation within its areas of operations. The Company has set the benchmark by developing 222 acres of green cover as of March 2016 around the periphery of the plant and installing Zero Discharge Unit, Sewage Treatment Plant and High Concentration Slurry Disposal (HCSD) system. |

|

|

|

| KCM has also commenced development of BMP for all its sites. The draft of BMP for Nchanga has been prepared and is undergoing review. Our efforts will yield the following benefits: |

- Enhancement of local livelihoods through sustainable forest management and climate change

mitigation

- Capacity building of communities and institutions to

adopt sustainable livelihoods and conservation of

forest resources

- Increased forest cover

- Reduced siltation and sedimentation of streams

and rivers

- Control over pollution and reduced erosion

- Enhanced GHG sequestration potential of the forest

and of degraded sites

- Improved biodiversity conservation, land and

watershed management

|

| Harvesting Plants at Gamsberg |

| In continuation of our biodiversity measures, we relocated ~90,000 plants to the Gamsberg Research and Rehabilitation Centre to help them survive a scant monsoon and a severe summer. We also donated plants to SANBI (Karoo Botanical Gardens-Worcester). |

| Butterfly Park at Pantnagar |

|

| Being responsible for pollination of more than 3% of the world's plants, butterflies play a very important role in the ecosystem. During our biodiversity study of 117 species of butterflies at Pantnagar Metal Plant (PMP), we found that most of the species were present in very low numbers. We decided to improve the habitat so that they would attract more of these ecologically important insect group. |

| A butterfly park in an area of 225 sq. m. was set up in the core zone near the admin block at PMP. 660 different seasonal and permanent flower varieties were planted to attract butterflies and an oasis (water pond) was made for the birds inside the plant premises. |

|

|

| |

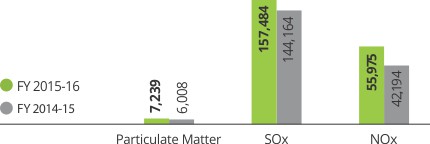

AIR QUALITY

| Our Environmental Management Standard commits all our operations to identify and manage emissions to air from point, fugitive and mobile sources, as well as from process activities associated with combustion and materials storage. |

| We monitor Suspended Particulate Matter (SPM), SOx and NOx as part of our ambient air quality monitoring process. We also keep in check lead emissions in our zinc operations, fluoride emissions in our copper and aluminum operations, and Polycyclic Aromatic Hydrocarbons (PAHs) in our aluminium operations. |

|

| Performance |

| Stack Emissions |

|

|

|

| Other emission include fluoride emissions (95 MT) - aluminium operations, lead emissions (36 MT), PAH emissions (14 MT) - zinc operations, and VOC emissions (226 MT) - Cairn India operations. |

| As part of our constant endeavour to enhance our air quality management outcomes, we undertook the following key initiatives during the reporting period: |

|

|

- Implemented good practice management and pollution techniques including Electrostatic Precipitators (ESP) to

minimise and manage our air emissions

- Regulated stack emissions of particulate matter at most of our operations

- Installed bag filters, scrubbers and dry fog systems with water sprinklers to minimise dust while transporting

extracted materials like bauxite, coal, lime and alumina. Covered trucks with tarpaulin to ensure no spillage or

dust generation

|

| Coal powers our power plants and to curb mercury emissions which may arise from naturally occurring trace impurity in the coal, we have deployed quenched tower, hot ESP, wet ESP and mercury removal towers to treat the gas prior to its release in the environment. Any by-product or waste, which may contain mercury, is recorded and disposed-off at authorised hazardous waste management sites, in accordance with local legal requirements. |

| |

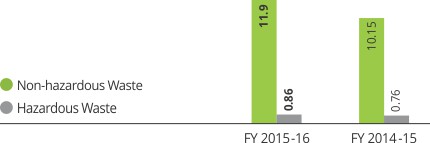

WASTE

| Our hazardous waste includes used/spent oil, waste refractories, spent pot lining and residual sludge from smelters. The non-hazardous (high volume, low effect) waste we generate includes fly ash (from captive and merchant power plants), red mud (aluminium refinery waste), jarosite / jarofix (from zinc smelting), slag, lime grit (process residues from smelters and aluminium refineries) and phospho gypsum (phosphoric acid plant). |

| Approach |

| Resource Use and Waste Management Technical Standard, and supporting guidance notes are part of the framework we have adopted. Our first priority is to reduce the waste, quantitatively as well as qualitatively (reducing the toxicity), which is followed by recovery and recycle (either ourselves or sold to authorised recyclers). Disposal in landfill or by incineration is the last option. In such cases, we use authorised, licenced and secured landfills. |

| Performance |

| We generated around 12 mn MT and recycled/re-used 50% of non-hazardous waste. Hazardous waste was stored in a secured landfill and some of it was sold to authorised recyclers. Further, around 102 mn MT of overburden and waste rocks and 27 mn MT of tailing were produced. Much of our generated waste rock and overburden is used in secondary construction work. For example in raising tailing dam heights, and back-filling mined out areas and exhausted mine pits. |

| HZL's state-of-the-art Central Research & Development Laboratory continues to explore how to recover more metals from mining & smelting operations, thereby minimising waste. |

| The total fly ash utilisation increased to 47% in FY 2015-16 from 31% in the previous year. At our Cairn operations, around 25,591 MT of drill mud and cuttings were produced using non-aqueous drilling fluid, out of which 100% was disposed at onshore and offshore facilities. |

| |

| Amount of Waste Generated |

mn MT |

|

|

|

|

| Owing to the increase in production, the amount of hazardous and non-hazardous waste too increased marginally. |

| |

| Fly ash recycling increased to 47% in FY 2015-16

from 31% in FY 2014-15 |

|

|

| CLOSING THE LOOP |

| |

|

| |

| |

|

|

FROM WORTHLESS

TO WORTHY |

| The framework of technical standards helps our subsidiary businesses to systematically identify all the opportunities available and practicable, to turn waste from worthless to worthy. |

|

|

| |

| FROM SLAG TO SLAB Vedanta Limited - Sterlite Copper |

| Copper Slag - a by-product generated from our pyro metallurgical smelting operations poses the following challenges: Land occupancy | Potential hazards of storage | Statutory obligations to dispose the copper slag |

| In our journey to find a solution, we carried out studies on the utilisation of copper slag in collaboration with the country's premier research institutions and found its usage as a sustainable alternative to sand in diverse infrastructure applications which include road and embankment construction, berth construction, cement & concrete applications, cement manufacturing, pavers manufacturing, abrasives etc. |

| In the year 2015-16, 46% of the copper slag produced was repurposed in sustainable applications. With ever increasing demand for natural aggregates from the construction sector, diminishing supply and environmental damage associated with sand mining, copper slag has emerged as an agent for industrial ecology. We will continue to find other such avenues for utilisation of copper slag. |

| |

| FROM ASH TO CASH Vedanta Limited - Lanjigarh |

| Challenge |

| The consumption of coal in coal-based power plants produces fly ash in large volumes, utilisation of which is an environmental challenge. |

| Action |

| In collaboration with Institute of Minerals and Materials Technology, Bhubaneswar (A CSIR laboratory), Vedanta developed a mineral cementation technology which utilises fly ash (>80% by weight) in the brick manufacturing process and lime grit as a binder. |

| We then encouraged & supported brick making units situated close to the plant by transferring the technology to them. Since last three years, we are conducting 'Fly Ash Manufacturing Enterprise Development' workshop in partnership with District Industries Centre, Bhawanipatna, leading not only to a sustainable alternative usage of waste, but also creating sustainable and profitable livelihood for the community around our units. |

|

|

|

|

| |

| Outcome Fly Ash Dashboard |

Total Ash Generated

207,185 MT |

Total Ash Utilised

118,228 MT |

% of Total Ash Utilised

57.06 % |

Ash Utilised in

Brick Manufacturing

34,790 MT

( 8,588 MT

in

FY 2014-15) |

% of Ash Utilised

for Brick Making

16.79 % |

|

| |

| FROM JAROSITE TO WASTE-FREE SITE A Future Action Plan at HZL |

| In the hydrometallurgical zinc processing, the iron commonly associated with zinc concentrate is removed through the Jarosite process. This process results in the generation of Jarosite, a hazardous waste which is treated with lime and cement to convert into Jarofix which is inert and suitable for disposal on lined yard. As land required for disposal is enormous, we are in the process of introducing alternative environment-friendly techniques, which are sustainable for long-term operations. |

| We have zeroed in on implementing an innovative 'Fumer Technology' patented by Xmetech, South Korea, in which zinc ferrite is fumed in a furnace, residual metal iscaptured as fume oxide and the waste is recovered as clean slag and can be used in cement and construction industries etc. |

| This project is at the planning stage and is expected to be actualised in the next year. Once implemented, it will accrue the below benefits: |

|

- Waste reduction at premises, thereby reducing environmental liability

- Increased recovery of Zinc, Lead, Silver, Copper and Sulphur

- Utilisation of available land for alternative use

- The fumer is energy positive. Gases from fumer pass through the Waste Heat Recovery boiler which

produce ~21 Mwh of green energy, out of which ~12 Mwh is utilised in the fumer and there is surplus

power of ~9 Mwh

- Fumer Slag contains ~7.6% lime and ~43% Fe2O3 and its usage in manufacture of cement reduces

consumption of CaCO3 by ~17,000 metric tons and also reduces the carbon footprint by ~7,700 tons

- Jarosite is converted to Jarofix with addition of lime and cement. Fumer operation eliminates the need for lime and cement

|

|

| |

|

|

| |

|

| |

| For more information visit our group companies |

| |

|

|

|

| |

|

|